Fall-arrest P.P.E: how to choose wisely?

Many workers are required to work at height: building and public works professionals, electricity network operators, company cleaning workers and maintenance technicians… Falls from height are the greatest cause of fatal accidents in the workplace.

When it is not technically possible to implement collective protection solutions, the use of Personal Protection Equipment (P.P.E) to prevent falls from height becomes mandatory. These personal protection systems are used to arrest the fall. P.P.E. can also be used to protect staff who are putting collective protection equipment in place, in situations where the operating methods do not remove the risk of falling.

Choosing equipment should be guided by what it will be used for, and should meet current standards.

Different applications

Work restraint

This system is designed to limit the user’s movements to prevent them from reaching zones where there is a risk of falling. It does not arrest a fall, and does not function as a work positioning or suspension system. It has an anchor point, a fall-arrest harness and a lanyard (which can be adjusted to make a fall impossible).

Current standard: EN 361

Fall arrest

A system designed to retain a user when they have fallen, and keep them suspended until assistance arrives. It has an anchor point, a fall-arrest harness and a fall-arrest device (a lanyard with an energy absorber, or a rope with a sliding or retractable fall arrester).

Current standard: EN 361

Work positioning

A system which enables a person to support themselves in a certain position using their feet whilst keeping both hands free for work. It has an anchor point, a fall-arrest harness with a belt for work positioning, and a positioning lanyard. If there is a risk of falling, this system should be supplemented with a fall-arrest device (a lanyard with an energy absorber, or a rope with a sliding or retractable fall arrester).

Current standard: EN 358

Suspension

A system designed for working whilst suspended in mid-air using an abdominal attachment point. As the user is no longer supported by their feet, the load is distributed at the height of the harness waist and thighs. Composed of an anchor point, a fall arrest harness, a fall arrest device (lanyard with energy absorber or a rope with a sliding fall arrester or reel) and a progression device.

Current standard: EN 813

How often?

Before making any purchase, it is important to know how often your P.P.E. will be used.

In fact, and particularly when buying a harness, you should define how often your equipment will be used so that you can choose the model which is the most suitable for your usage needs. The greater the frequency of use, the greater the need to choose a robust model.

Fall-arrest system considerations

Several factors should be taken into account in order to choose the equipment which is most suitable for your needs:

The fall factor

The fall factor measures the severity of a fall. There are 3 fall risk levels (0, 1 and 2) which are calculated according to the position of the anchor point in relation to that of the user. It is strongly recommended to have the anchor point above the user to limit the impact force.

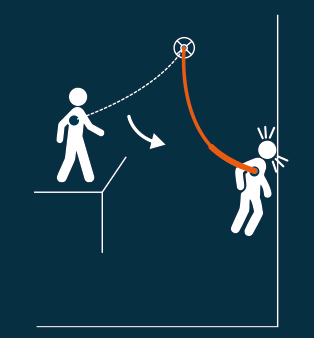

The pendulum effect

The pendulum effect is the risk of lateral movement for the user during a fall. This effect can result in a collision with the floor or an obstacle and can cause serious injury. The lanyard anchor point should therefore be positioned as far away as possible from an obstacle, and situations with a fall factor of 2 should be avoided.

Clearance

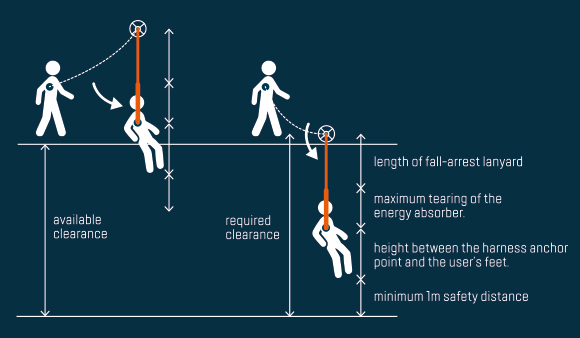

Clearance is the necessary distance between the anchor point and the floor surface. It varies according to the position of the anchor point and the fall-arrest device chosen. The available clearance is the distance between the structure the user is working on and the nearest obstacle. The required clearance is the minimum distance a user can fall without a risk of hitting the floor or the nearest obstacle.

Checking P.P.E.

Like any worksite equipment, personal protection equipment (P.P.E.) is subject to wear, deterioration, dirt, etc. To comply with legislation, and to be certain of using equipment which is in perfect condition, all P.P.E. should undergo an annual inspection. The inspection record should be logged in the safety register. If there is any doubt, immediately withdraw the product from circulation.

In any situation, two types of inspections should be carried out to best ensure users’ safety:

1. First inspection by the user before using the P.P.E.

This quick, but important, inspection should be carried out by the user before using the P.P.E. to ensure that it is compliant and in perfect condition to provide all-round safety.

This is a mandatory inspection, and is set down in the decree of 19 March 1993 – article R. 233-42-2 of the French Labour Code. This inspection requires each user to be trained and vigilant about detecting problems with their P.P.E. equipment.

2. Second regular annual equipment inspection

It is mandatory to carry out a regular annual check of your equipment by qualified individuals. This inspection is essential for guaranteeing the safety of employees in their work.

Your P.P.E. should be inspected by qualified individuals: employees or external organisations. These individuals should be specially trained to carry out all relevant inspections on your personal protection equipment.

If no anomaly is detected, a P.P.E. inspection certificate is issued to the company, certifying the conformity of the equipment used.

We provide P.P.E. inspection sessions which are run by our access at height experts, and ensure the monitoring and upkeep of products in the best way possible.

A registration system for your P.P.E. is available on our site. You will receive your registration certificates, alerts for inspection dates, and regulatory and standards information by email.